WE ARE MAZDA

THE ROTARY ENGINE LIVES ON

An exclusive look at the 13B Rotary Engine Factory—the story of continued production

We refuse to let the dream engine end as a dream. Introducing the people, factory, and vision behind the ongoing production of Mazda rotary engines.

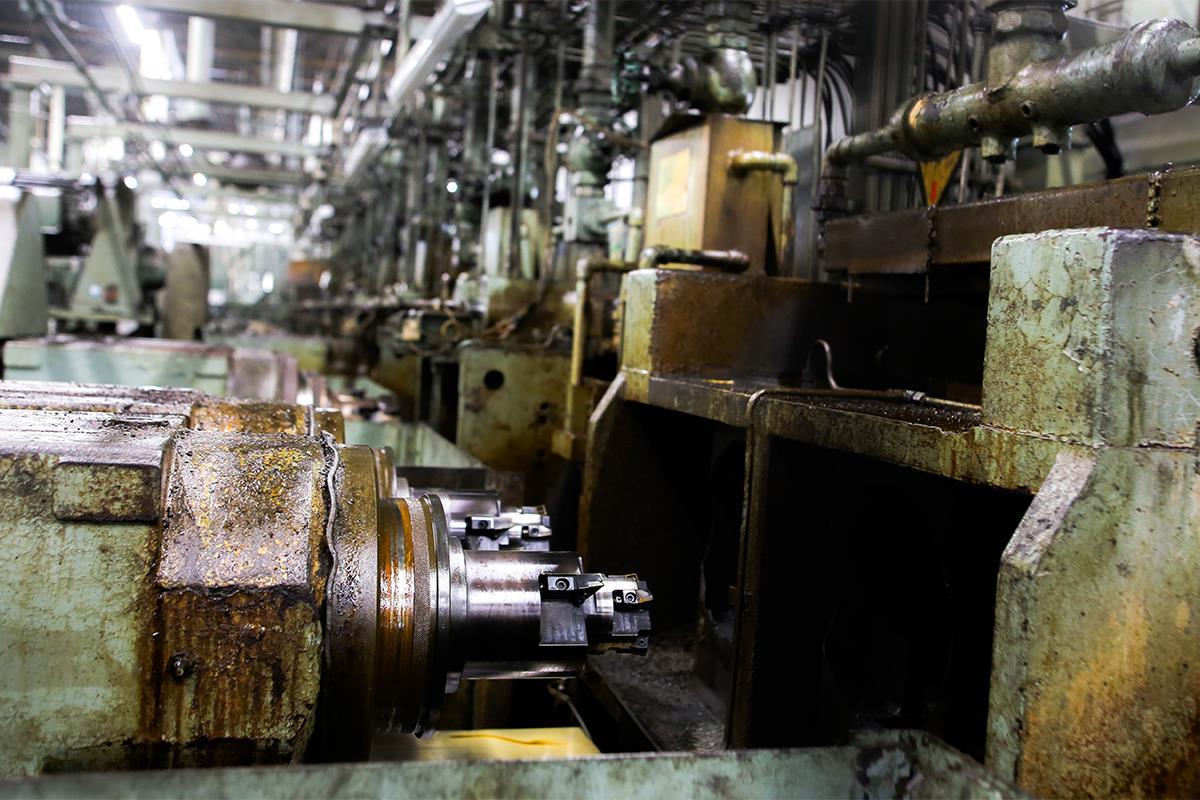

It’s half past eight in a dimly lit factory in Hiroshima, Japan, one morning in 2021. A light comes on, followed by the dim hum of machines as far as the eye can see coming to life. We’re in Mazda Powertrain Production Department No. 2, where 13B rotary engine parts are made. Yes, the rotary engine lives on!

For our younger readers, who are still dreaming of the day they can get their license and embark on a life with their own car, these machines would have first come to life around the time your grandparents were dreaming the same thing. In fact, they may have been born around the same time as your mom or dad!

Back then, Mazda was known as Toyo Kogyo, and we had huge dreams for the future of cars. Surely, a car that was intuitive to drive could heighten our sensibilities and make life so much more fun? The rotary engine—that delivers smooth, powerful acceleration that seems to increase endlessly the more you press on the pedal—embodied Mazda’s dream to create exactly that kind of car.

The smell of oil from the warming machines signals a new day on the factory floor. I slowly make my way further into the factory between the towering machines. Come join me on this tour of the only rotary engine factory in the world.

Painstakingly hand-manufactured using the same machinery as the original rotary cars.

Each 2021 13B rotary engine is carefully pieced together by a small team of expert engineers.

The first person I came across was none other than Mazda’s longest serving rotary engineer himself—Tetsuya Sato. And no surprise, even after 36 years with the company, he was still hard at work on a processing machine! He shared some insight into why he’s so passionate about the rotary engine.

“Mazda started producing rotary engine parts in this factory 1973. All our processing machines date back to this era, which means they’ve been working tirelessly for over half a century. Precise processing demands precise machinery, so it’s crucial that we carry out daily maintenance on these machines. Not many people are aware of this, but we’re actually still producing the Mazda rotary engine. Although the Mazda RX-8 was the last model to actually use a 13B rotary engine and production of the RX-8 finished in 2012, we’re still producing spare parts and engines made using these parts. That’s why this factory still exists.”

Looking up at a bulky, ironclad processing machine that certainly looked like it’d been hard at work for several decades, Sato continued.

“Our predecessors entrusted these machines with their hopes and dreams. They’re not as capable as today’s computer-controlled machines—for example, all the machines in this area are cutting machines, but the blade on each machine can only be moved in one direction. So, once we’ve finished processing on one machine, we have to take the part out and set it up in the next. It takes working through about forty machines—starting with the one by the door where you came in—to finish the basic processing for a single rotor.”

“They might be old, but these are wonderful machines that were cutting-edge at the time and were carefully designed to produce meticulous results—a true testament to the innovation and ingenuity or our predecessors. I know this as surely as I know myself, because I’ve worked with these machines for 36 years. Here, let me show you how our 2021 13B rotary engines are made.” Sato led me deeper into the factory.

Maintaining optimal manufacturing conditions is the first step in ensuring optimal quality.

Next, we stop to talk to Yoshikazu Washio, another rotary engineer hard at work.

“What I’m doing here is cutting the grooves where we attach the apex seals. These seals are attached at all three points of the triangular rotor and are crucial for optimizing rotary engine performance.”

“The design value for the groove width is 2 mm, and we finish these to within an accuracy of 5 to 12 thousandths of a millimeter, carefully whittling away at the groove using a revolving grindstone. But the actual first step in this process is to carefully check the thickness and condition of the grindstone, because they can thin with use. Even a tiny scratch on the surface of the stone can damage the inner wall of a groove. A minor fault in any one of these machines can waste all the hard work put into processing the rotor up to this point. It’s crucial that we avoid this by making sure everything is in prime working order before we start each process.”

Washio is also a veteran engineer with 35 years’ experience crafting rotary engines in this factory. He has a reputation among his colleagues for being shy and gentle and, true to form, he got straight back to work as soon as he’d answered my question.

“We only have a small team of seven people involved in rotary engine production on-site. Add in a few other engineers who do the first half of the rotor housing processing in another building nearby and we’re a team of ten. This small team makes all the parts needed for a rotary engine—including the rotor housing, side housing, and eccentric shaft in addition to the actual rotors. It’s not easy, but we’re a team and we’re in it together. Everyone on the team is unique—it’s a fun place to work.”

Sato smiled and headed off again.

The rotary dream team—ten expert engineers who craft all ten variations of the 13B rotary engine.

Sato smiles again as he drops some impressive figures. His team ships out the equivalent of two to four hundred engines worth of rotary engine parts on average each month.

Next, I spoke to Hiromichi Abe and Naoki Mitsu who joined the team in April 2020 as foreman and assistant foreman, respectively. They agreed in their assessment of their teammates:

“Depending on the car it’s for and the engine specifications, there are ten different variations of the 13B rotary engine, and each variation uses slightly different parts. All these parts—and there’s a lot—are made to order for customers in all corners of the world. Some parts can take between one to two months to process to completion, including work done in-house and externally. On top of this, we sometimes need to assemble these parts into a particular unit,” explains Abe.

“The fact that our team can successfully carry out these complex processes is a testament to their communication and teamwork. Everyone that works here has the skills and experience to perform multiple processes perfectly. Working here, you’ll regularly see workers moving between tasks and machinery that require completely different skills sets. What makes this possible, and really sets this team apart, is their teamwork—their willingness to help each other out and take on tasks outside of their own roles,” agrees Mitsu.

I asked Sato whether he thought the job was tough.

“My colleagues that joined Mazda around the same time as I did, did so because it was our dream to work on the rotary engine. While they’re no longer being used in new cars, we’re the generation that truly understands the vision behind this engine, and we know a large number of customers across the globe also resonated with this vision and purchased Mazda rotary cars. We want to make sure these customers can continue to enjoy the thrill of driving a rotary-powered car long into the future.”

“The best thing about working here is the great teamwork and comradery. The work of producing each engine manually is hard, but we do it in a team where we’re face-to-face with everyone, every day, so we get a sense of shared responsibility and ownership.”

With this, he walked further off into the distance between the rows of giant machines.

Next up: The Intricate Process That Makes Each Rotary Engine a Work of Art