Mazda’s gigantic presses: the secret to their 52-year long service

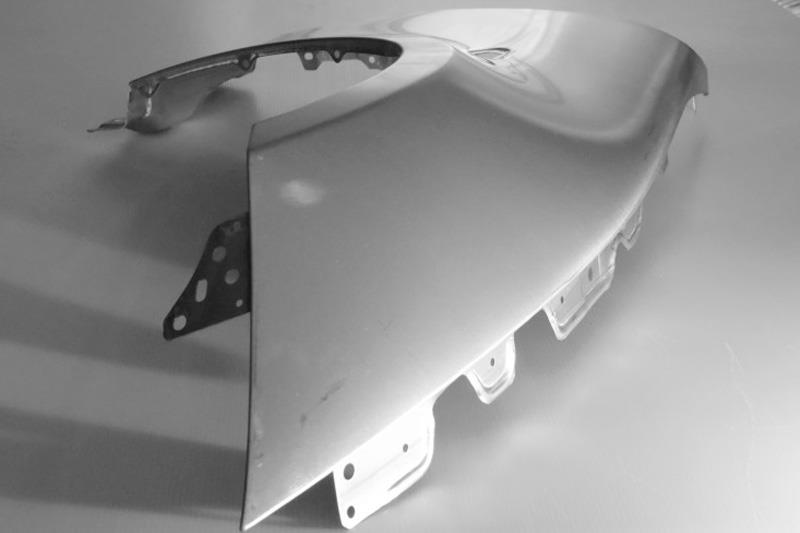

At Mazda’s Ujina stamping plant, 52 presses produce body parts for the CX-5, CX-3, CX-9 and MX-5 among others, with the largest weighing in at 5,200 tonnes.

Even more astonishingly, some have been in service for 52 years and still carry out the most important tasks in the production process. So how do these machines manage to stay on the frontline of manufacturing? We find out the secret.

Like a parent’s love for their child

The staff who conduct the refuelling, inspection and maintenance of the presses work virtually every day of the year. If a part requires an inspection, they check it with their own eyes. The drive unit, the heart of the press, is constructed like a sealed box so there is no room to move around, and the surrounding space is covered in lubricant oil. Even in these harsh conditions, the staff are driven by their passion to carry out any inspection necessary – and that’s the secret to why these gigantic presses have been working for 52 years.

‘Even if it’s like a sauna and sticky with oil, our curiosity gets the better of us,’ says Kikuchi, who is in his 17th year in the maintenance team. ‘Where it’s too small for human access, we use fibrescopes. As we get to know the presses, we develop a love for them that’s almost like a parent’s love for their child.’

An expert’s skills

A key inspection area within the drive unit is a large gear wheel that’s three metres in diameter. While a rookie might take an hour to inspect one of these, an old hand can do it in roughly ten minutes. Years of experience have taught them to understand the structure of the press and the gear wheel, decide exactly which of the hundred-plus teeth on the wheel needs inspecting and carry out an efficient quality check. These experts use their honed senses to feel a faulty gear with its discoloured, bumpy surface for depth, breadth and shape, and make an instant diagnosis.

The expert’s skill can be seen in other processes. Quality checks on the motor are conducted on the motor itself and the bearings within using a vibration meter, whose acceptable measurement range is set by the manufacturer. However, at a stamping plant where there are always many different vibrations, the acceptable range is never constant even within the same press or the same motor.

Astonishingly, the actual range is set by Kikuchi himself who uses his own ears and a stethoscope stick.

‘Each motor is different, but usually if it’s running well it lets off very delicate vibrations, like a ringing sound that reverberates from the temple into the brain.

If the grease on the bearings starts to deplete or deteriorate, the ringing tone heightens, and if it gets worse very fast tick tock sounds appear within the ringing tone.’

This skill took Kikuchi 17 years to perfect. When he was first learning the trick from a senior member of staff, he tried to recognise and memorise the different vibrations but failed over and over. ‘Looking back it’s because I had such a frustrating experience that I was ultimately able to master it. I hope to continue on the road to becoming a ‘takumi’ (craftsman) of press maintenance by building up these sorts of skills.’

Passing on the human touch

Diagnostic technology will continue to develop, but human sensory skills will always be the foundation. This is specially the case at the stamping plant where long-serving presses require skills to be passed on down the generations.

Mazda’s press maintenance team are doing just that, sharing their sensory expertise to see, touch, feel and smell, and challenging themselves to carry out ever more precise quality checks.

Other Stories

Driving stories on the great & challenging roads and journeys

Stories about the craftsmanship and design evolution of Mazda

Visions and philosophies of Mazda engineers

The spirit of Mazda owners, collectors, clubs and aficionados around the world

Mazda brand heritage and history