One of the Secrets Behind Soul Red: Mazda’s Electro-deposition Basecoat Enhances Brilliance and Beauty of KODO Design

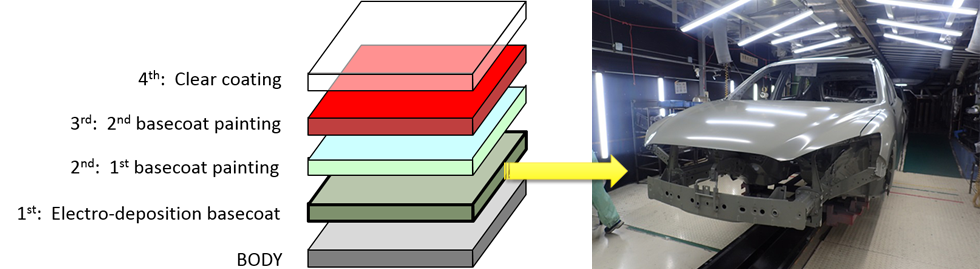

Mazda’s famed KODO Design would not look so good without an array of attractive body paint colours. Here comes a question – how many paint layers does the new-generation Mazda get? The answer is 4, and that is shocking news given that the Mazda Soul Red body paint is only 0.08 millimetres thick. That translates to a thickness of just 1 photocopying paper.

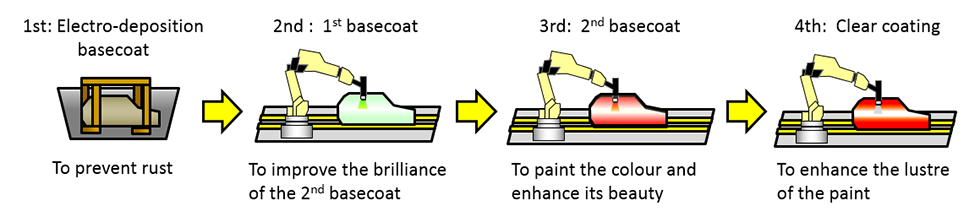

At Mazda, each car gets painted by following a 4-step process. The painting process starts with electro-deposition basecoat or the first layer, followed by the first basecoat, second basecoat and clear coating. Each coat is designed for different purposes such as rust prevention, improving brilliance of color, or enhancing beauty and luster of the paint.

<Process of Body Paintings>

<Composition of four paint layers>

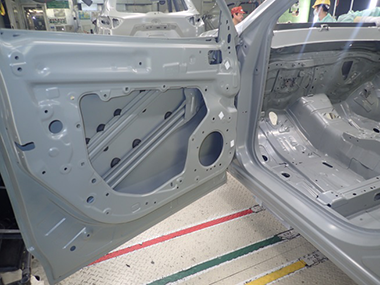

<1st layer: Electro-deposition basecoated body>

<Final (4th) layer: Clear coated body>

The first layer or the base, which is called electro-deposition basecoat, plays a vital role in maintaining the beauty of body colour even though it remains invisible when a car is fully assembled and ready to ship. Insufficient base may result in paint peeling caused by paint losing adhesiveness over time. Worse, the car’s appearance can be minimized with uneven body surface caused by poor basecoat.

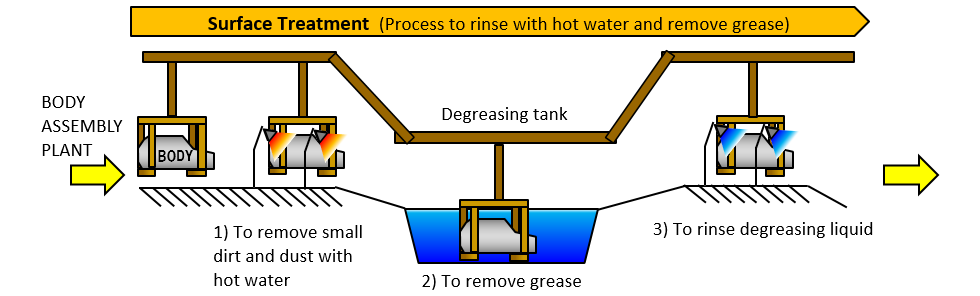

Electro-deposition basecoat is done in a 3-step process. The first step is called surface treatment, where a car gets fully rinsed with hot water (as pictured) to remove small dirt and dust. Then the car is put into a degreasing tank to remove grease.

<First Step>

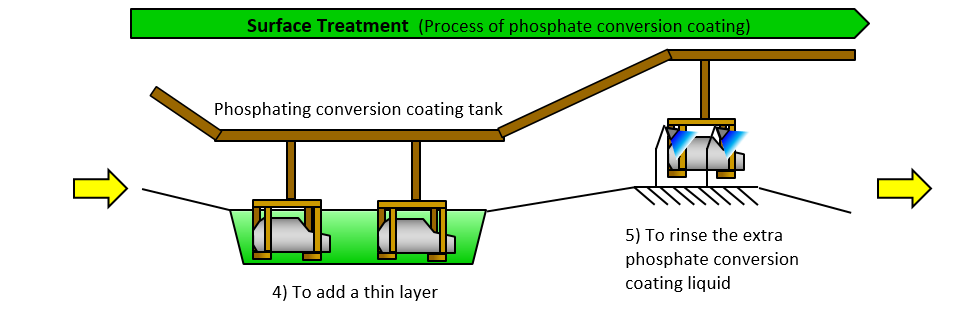

The second process also involves surface treatment, but this step deals with phosphate conversion coating. The car is soaked in a phosphating conversion coating liquid to add a thin layer, which improves paint’s adhesiveness and gives a beautiful finish.

<Second Step>

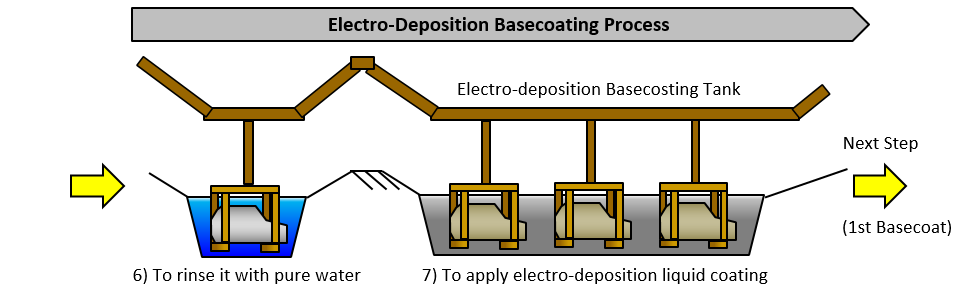

The last step deals with “electro-deposition coating”, where electro-deposition liquid coating paint, which takes advantage of electrical properties, is evenly applied to the car’s body. Electricity is generated from the positive electrode layer, which makes positively charged electro-deposition basecoat adhere to negatively charged car’s body – not only body surface but inside doors and hood, i.e. all over the car. The electro-deposition liquid coating paint prevents rust and ensures longevity of the car’s beautiful paint layers.

<Last Step>

A tank used in the process is filled with a solution using varieties of chemicals. To keep the solution in an ideal concentration that can easily fluctuate, the solution is managed and monitored 24/7 using 37 inspection facilities and a check-list containing 214 check items by the dedicated staff.

Fumio Saito (pictured), who manages the electro-deposition coating process, says, “we’re proud of our workplace because we play a critical role in maintaining a beautiful body paint over time. We never make compromises, everyone here is committed to keeping electro-deposition liquid coating paint in the best condition because we are a part of the process of manufacturing cars that are loved by customers for years on end.”

Next time you see the new-generation Mazda on the street, remember that their efforts, expertise and skills are “layered” under its brilliant body paint, invisible to the eye.

Other Stories

Driving stories on the great & challenging roads and journeys

Stories about the craftsmanship and design evolution of Mazda

Visions and philosophies of Mazda engineers

The spirit of Mazda owners, collectors, clubs and aficionados around the world

Mazda brand heritage and history