Crash Testing – the Ultimate Test of Master Engineer’s Skills (Vol. 1)

You may have seen a vehicle crash testing on TV using dummies. For car companies, the moment of crash is when a measurement is taken on various data which are used to ensure vehicle safety. A crash test would not be possible without “crash-test dummies” – dolls that replace human passengers. Those poor dummies go through a full impact of crash, allowing engineers with car companies to measure the effect and the impact of crash, called injury value, on a human body.

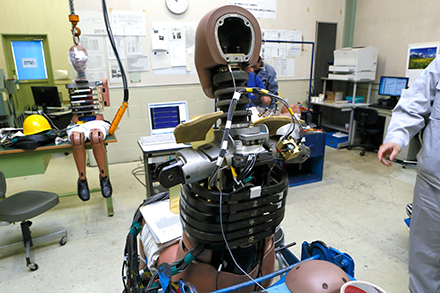

Crash-test dummies are not just dolls; they are precision measuring instrument made up of human skeletal frame covered by rubber skin. Inside the frame are numerous sensors which are mounted for a specific purpose of each crash test. Tatsuhiko Iwamoto is a guy who knows crash-test dummies inside out. A master engineer with Mazda’s Crash Safety Development Department, Iwamoto’s job is to review and determine specifications of occupant restraint devices such as seat belt and air bags to achieve goals set for each test, by taking intricately complex factors into consideration.

The crash itself is instantaneous, in fact it only takes less than 0.1 second. But engineers take tremendous amount of time and work to prepare for that mere 0.1 second. With mounting consumer awareness of vehicle safety today, multiple tests such as “full-wrap”, “offset” and “oblique” are conducted as a part of frontal collision testing. Crash test also measures impact generated from side and read-end collisions, and the testing requirements vary depending on the destination of export. That means numerous crash testing is conducted for development of each new model, and different requirements must be met for different destinations. All of that puts a huge responsibility on Iwamoto’s shoulders.

Mr. Tatsuhiko Iwamoto (master engineer)

The dummy having the number of built-in sensors

Toshimi Shimooka is one of Iwamoto’s staff who plays a critical role. An employee with Mazda E&T, one of Mazda’s business partners, Shimooka says, “I immediately and instinctively know the conditions of the crash-test dummies by just looking at them”. He is responsible for managing tens of the crash-test dummies which are different in age, gender and build, under stringent standards such as temperature and environment to name but a few.

“Following your own unique way is a cardinal sin in what I do”, he says. Because, he continues, aiming to hit the standard figure within the pre-determined scale by following detailed regulations is the most important thing.

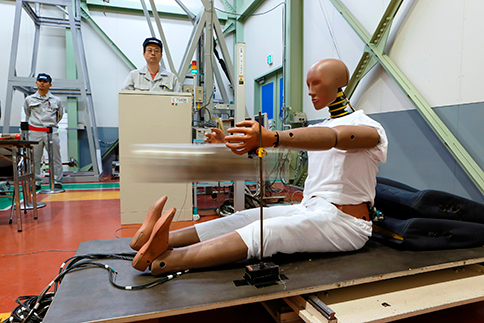

In frontal collision testing, a crash-test dummy goes through 9 examination articles. Key articles are rigidness of rubber covering measurement sections and dynamic resistance of joints. For the chest section, the dummy’s chest is hit by the weight as specified by the regulation. The process is repeated with adjustments made on the “rib” section. “Per chest, we make sure that error range is always within 1mm”, Shimooka says with the pride of a master engineer. Iwamoto fully recognizes and appreciates his effort, and says “having access to crash-test dummies which are kept at the exact same conditions is making a huge contribution to Mazda’s crash testing accuracy, which really is the foundation of Mazda’s vehicle safety”.

The moment when the weight hits the dummy’s chest

Mr. Toshimi Shimooka (master engineer of Mazda E&T)

Various sensors of the dummy

Although Iwamoto and Shimooka work with different companies – one with Mazda Motor Corporation and the other with its business partner, they respect one another’s skills and commitment, and work together to make an ongoing improvement. Such a partnership with a healthy competition lies at the bottom of Mazda’s vehicle safety.

But we have only gone as far as the examination of crash-test dummies. How are they mounted in test cars? That will be the subject of Volume 2, which covers “dummy set” – setting up a crash-test dummy in a car.

Other Stories

Driving stories on the great & challenging roads and journeys

Stories about the craftsmanship and design evolution of Mazda

Visions and philosophies of Mazda engineers

The spirit of Mazda owners, collectors, clubs and aficionados around the world

Mazda brand heritage and history